Introduktion: Grundlaget for en perfekt t-shirt Den ydmyge t-shirt er en global garderobe, men ikke alle t-shirts er skabt lige. Den dybe forskel mellem en gennemsnitlig skjorte og en, der føles...

Læs mereskik Uldpolyesterstoffer

Wool-Polyester-stof kombinerer varmen og komforten af naturlige fibre med holdbarhed og letplejeegenskaber af syntetiske fibre. Stoffet er en blanding af udvalgte uld og højstyrke polyesterfibre. Det opretholder ikke kun de naturlige fordele ved uld, såsom varme, åndbarhed, fugtabsorption og fjernelse af sved, men også inkorporerer de praktiske egenskaber ved polyester såsom rynkebestandighed, slidstyrke og let pleje, opnåelse af komplementær og optimeret ydeevne. Wool-Polyester-stoffet har god farveudtryk, og hurtighed kan tilpasse sig forskellige designs og personaliserede behov og er vidt brugt i erhvervsmæssigt slid, afslappet slid og boligindretning. Det har stærk rynke modstand og god elastisk bedring. Selv hvis det er båret i lang tid eller vasket ofte, kan det holde tøjet fladt og sprødt, hvilket i høj grad reducerer kompleksiteten i den daglige pleje. Med sine unikke blandingsfordele viser uldpolyesterstof god omfattende ydelse og bliver et ideelt valg for forbrugere, der forfølger et liv i høj kvalitet og professionelt image, hvilket afspejler den gode kombination af moderne tekstilteknologi og naturlige materialer.

-

-

Som tekstilingeniør og beklædningsgenstand udbyder af løsninger, vores virksomhed er specialiseret i indkøb, evaluering og levering af avancerede stofmaterialer til beklædningsproducenter, mærker o...

Læs mere -

1. Hvorfor er en silkebomuldsblanding det smarte valg til eksklusive specialskjorter? Jagten på det perfekte skjortestof fører ofte til et klassisk dilemma: den luksuriøse følelse af silke versu...

Læs mere -

Udforsk fordelene ved Jacquard Mercerized strikstof til følsom hud Personer med følsom hud kæmper ofte med at finde tekstiler, der giver komfort uden at forårsage irritation, hvilket er her den ...

Læs mere -

Udpakning af Supima Cotton Fibers overlegenhed Den ekstra lange hæftefordel: Holdbarhed og blødhed Grundlaget for dette enestående tekstil ligger i brugen af Supima bomuld, en sort kendt...

Læs mere

How to control the blending ratio of wool polyester fabrics? Are the blended fibers specially treated to enhance spinnability?

The blending ratio of wool polyester fabrics is directly related to the performance and application areas of the final product. Reasonable blending ratio design needs to give full play to the complementary advantages of the two fibers on the basis of maintaining the original advantages of the fabric to achieve the best wearing experience and use effect.

Principles for selecting blending ratios

Performance demand orientation: Determine the blending ratio according to the final use of clothing or home decorations. For example, business formal wear pays more attention to the stiffness and wrinkle resistance of the fabric, which may increase the proportion of polyester fiber; while casual wear or household items may prefer the softness and breathability of wool, thereby appropriately reducing the content of polyester fiber.

Cost-effectiveness considerations: Wool, as a natural fiber, is relatively expensive, while polyester fiber is more economical. Reasonable blending ratios need to consider production costs while ensuring fabric quality to maximize cost-effectiveness.

Wearing comfort: The blending ratio also needs to consider the wearer's comfort, such as the warmth and breathability of wool, and the wrinkle resistance and easy-to-care nature of polyester fibers, which need to be balanced in the ratio setting.

Specific control of blending ratio

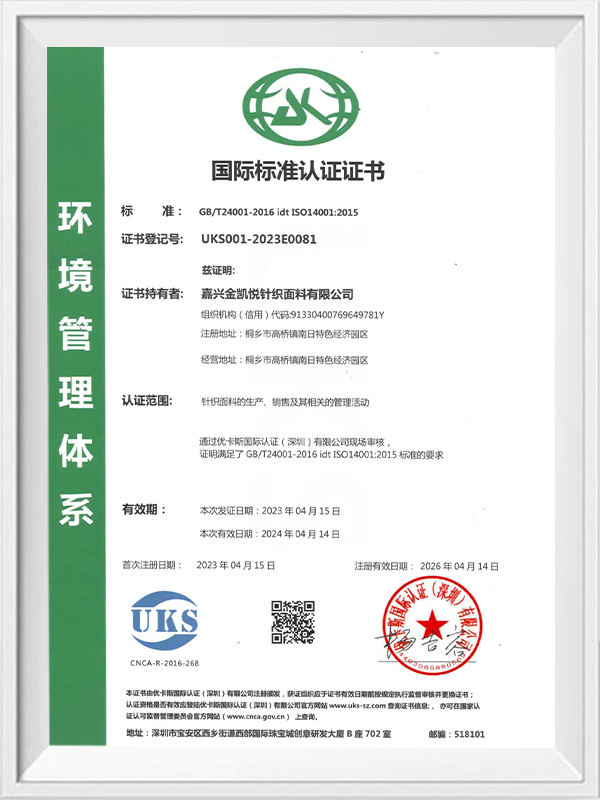

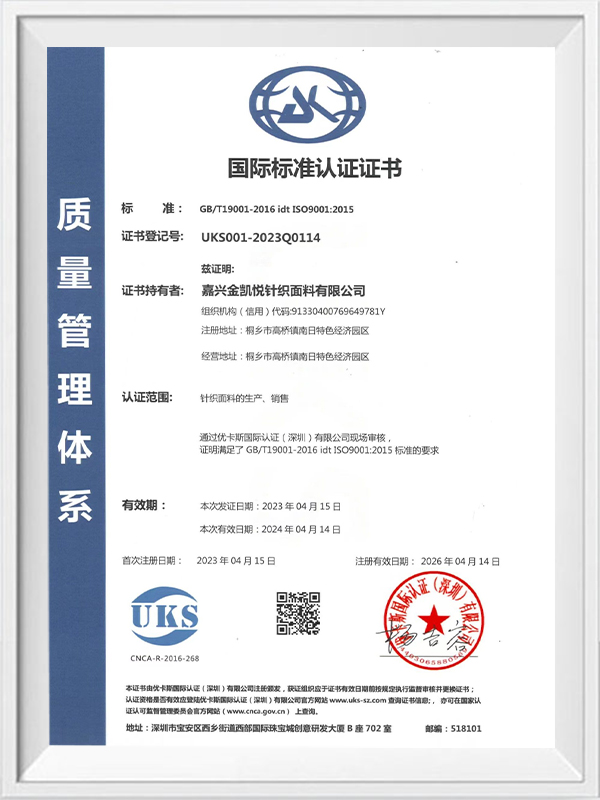

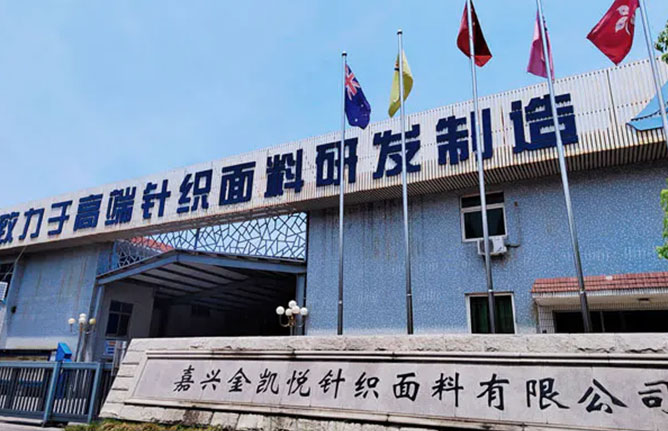

Raw material selection and proportioning: When producing wool-polyester fabrics, Jiaxing Jinkaiyue Knitted Fabric Co., Ltd. selects high-quality wool and high-strength polyester fibers as raw materials, and ensures that each batch of fabrics can reach the preset blending ratio through a precise proportioning system. The company uses advanced metering equipment to accurately weigh the raw materials to ensure the accuracy of the blending ratio.

Optimization of blending process: During the blending process, the company uses advanced blending technologies, such as air-flow blending and drawing blending, to ensure that wool and polyester fibers are evenly mixed at the fiber level to avoid fiber agglomeration and affect fabric performance. By adjusting the blending process parameters, such as blending temperature, humidity, speed, etc., the blending effect is further optimized.

Testing and verification of blending ratio

Physical property test: After blending is completed, the physical properties of the fabric need to be tested, including tensile strength, tear strength, abrasion resistance, wrinkle resistance, etc., to verify whether the blending ratio achieves the expected effect.

Chemical property test: Check the color fastness, shrinkage, acid and alkali resistance and other chemical properties of the fabric to ensure that the fabric can remain stable under different environments.

Sensory evaluation: Through the sensory evaluation of experts or consumers, subjective judgments are made on the feel, gloss, breathability, etc. of the fabric, and the rationality of the blending ratio is comprehensively evaluated.

In order to improve the blending effect of wool polyester fibers and enhance the spinnability of the fabric, special treatment of the blended fibers is usually required. These treatments can not only improve the blending uniformity of the fibers, but also improve the overall performance of the fabric.

Pretreatment of wool

Anti-shrinkage treatment: Wool has a natural shrinkage property, which can easily cause the fabric to shrink and deform. Through chlorination or bio-enzyme treatment, the wool scale layer is destroyed, the shrinkage property is reduced, and the dimensional stability of the fabric is improved.

Softening treatment: Wool is pretreated with a softener to improve its feel, make it softer and smoother, and improve wearing comfort.

Antistatic treatment: Wool is prone to static electricity, which affects the wearing experience. By adding antistatic agents, static electricity can be effectively reduced and the skin-friendliness of the fabric can be improved.

Modification of polyester fiber

Fine denier treatment: Through chemical or physical methods, polyester fiber is refined to make it softer and more drapable. After blending with wool, the fabric is more delicate and light.

Hydrophilic modification: Polyester fiber itself has poor hydrophilicity. Hydrophilic groups are introduced through copolymerization, grafting and other methods to improve the moisture absorption and perspiration performance of the fiber, which complements the breathability of wool.

Anti-ultraviolet treatment: Anti-ultraviolet agents are added to polyester fibers to enhance their anti-ultraviolet ability and protect the wearer from ultraviolet damage. It is suitable for outdoor clothing.

Compatibility treatment of blended fibers

Interface compatibilizer: Use interfacial compatibilizer to treat blended fibers to improve the interfacial bonding between wool and polyester fibers and improve the uniformity and stability of blended fibers.

Plasma treatment: Use plasma technology to modify the surface of blended fibers, increase the active groups on the fiber surface, promote mutual penetration and bonding between fibers, and improve the blending effect.

Vores produktionskapaciteter matches af stærke forsknings- og udviklingskapaciteter, hvilket gør os i stand til at levere et stort antal projekter med bedre kvalitet og kortere tidsfrister.

Produktionskapaciteter

Stærke produktionskapaciteter forbedrer din konkurrenceevne

-

For at sikre bedre kvalitet har Jin Hyatt investeret i banebrydende maskiner fra Italien, Tyskland, Schweiz, Japan og Taiwan.

-

Virksomheden beskæftiger sig primært med en række forskellige materialer, herunder morbærsilke, flydende ammoniakbomuld, uld, kashmir, udendørs sportsstoffer og forskellige fiberblandinger.

-

Virksomheden styrer effektivt opbevaring af råvarer og færdigvarer, integrerer hele produktionsprocessen og forbedrer den samlede effektivitet.

-

Virksomheden målretter sig mod high-end-markedet med strikkede stoffer af høj kvalitet og bruger 20% af sin arbejdskraft på forskning og udvikling for at forbedre produktets værdi og konkurrenceevne.

中文简体

中文简体