Introduktion: Grundlaget for en perfekt t-shirt Den ydmyge t-shirt er en global garderobe, men ikke alle t-shirts er skabt lige. Den dybe forskel mellem en gennemsnitlig skjorte og en, der føles...

Læs mereskik Ren bomuldstrøje stof

Cotton-spandex-shirtstoffet kombinerer omhyggeligt den naturlige komfort af bomuld med de elastiske fordele ved spandex, hvilket giver dig en god slidoplevelse. Andelen af bomuld i stoffet er helt rigtigt, som ikke kun bevarer den klassiske struktur og åndbarhed af bomuldstøj, men også sikrer tøjets holdbarhed og hudvenlighed. Tilsætningen af spandex tilføjer god elasticitet og bedring til stoffet, hvilket sikrer, at tøjet passer til kropsform og sand tretches frit og uhindret, hvad enten det er daglige aktiviteter eller let træning. Med hensyn til berøring er dette bomuldsspandex-shirt stof delikat og blød, passende som et andet lag med hud, hvilket giver dig blid pleje hele dagen lang. Dens gode fugtabsorption og svedpræstation kan hurtigt absorbere og fordampe sved, selv i den varme sommer- eller højintensitetsaktiviteter, holde kroppen tør, effektivt forhindre lugt og holde dig frisk og selvsikker til enhver tid. Med hensyn til design er skjorten lavet af bomuld-spandex blandet stof let at pleje, uanset om det er maskinvask eller håndvask, kan den let håndteres, hvilket sparer tid og kræfter. Dens lette og åndbare egenskaber gør skjorten til et passende valg i alle sæsoner.

-

-

Som tekstilingeniør og beklædningsgenstand udbyder af løsninger, vores virksomhed er specialiseret i indkøb, evaluering og levering af avancerede stofmaterialer til beklædningsproducenter, mærker o...

Læs mere -

1. Hvorfor er en silkebomuldsblanding det smarte valg til eksklusive specialskjorter? Jagten på det perfekte skjortestof fører ofte til et klassisk dilemma: den luksuriøse følelse af silke versu...

Læs mere -

Udforsk fordelene ved Jacquard Mercerized strikstof til følsom hud Personer med følsom hud kæmper ofte med at finde tekstiler, der giver komfort uden at forårsage irritation, hvilket er her den ...

Læs mere -

Udpakning af Supima Cotton Fibers overlegenhed Den ekstra lange hæftefordel: Holdbarhed og blødhed Grundlaget for dette enestående tekstil ligger i brugen af Supima bomuld, en sort kendt...

Læs mere

How to ensure the purity and fiber length of pure cotton shirt fabrics to improve the overall quality of the fabric

Pure cotton shirts are popular among consumers because of their natural softness, good breathability and good moisture absorption. In order to ensure the high quality of pure cotton shirt fabrics, purity and fiber length in the production process are two key factors.

Ensure the purity of fabrics

Purity is an important indicator to measure the impurity content in fabrics. Impurities in pure cotton fabrics may come from multiple links such as cotton planting, picking, and processing. In order to ensure the purity of fabrics, the following measures can be taken:

Selected raw materials: Choosing high-quality cotton as raw materials is the basis. High-quality cotton such as Xinjiang long-staple cotton and American Pima cotton has long fibers, high strength and few impurities, which is an ideal choice for making high-quality pure cotton fabrics.

Fine processing: In the cotton processing process, advanced impurity removal technologies such as airflow impurity removal and electrostatic impurity removal are used to effectively remove impurities such as cotton seeds, short fibers, dust, etc. to ensure the purity of fabrics.

Strict quality control: In the production process, a strict quality control system is established to regularly test and monitor the impurity content of fabrics to ensure that each batch of fabrics meets high quality requirements.

Ensure fiber length

Fiber length is an important factor affecting the feel and durability of fabrics. Long fibers make fabrics softer, smoother, and less prone to pilling and deformation. To ensure fiber length, the following measures can be taken:

Prefer long-staple cotton: As mentioned above, long-staple cotton has a longer fiber length and is the first choice for making high-quality pure cotton fabrics. By selecting long-staple cotton varieties, the fiber length of the fabric can be ensured.

Optimize spinning process: In the spinning process, the use of advanced spinning technologies such as compact spinning and siro spinning can effectively reduce fiber damage and short fibers, and retain the original length of the fiber.

Reasonable cotton matching: In the cotton matching process, according to the purpose and requirements of the fabric, cotton of different lengths and qualities are reasonably matched to ensure that the fiber length of the fabric meets the design requirements.

Improve the overall quality of the fabric

In addition to ensuring purity and fiber length, the overall quality of the fabric can be further improved through the following measures:

High-count and high-density weaving: The use of high-count and high-density weaving technology can make the fabric more delicate and crisp, and improve the gloss and wearing comfort of the fabric.

Post-treatment process: Through post-treatment processes such as singeing, mercerizing, and stentering, the feel, glossiness, and dimensional stability of the fabric can be further improved.

Environmentally friendly production: Environmentally friendly dyes and auxiliaries are used to reduce pollution emissions during the production process, while ensuring the environmental performance and safety of the fabric.

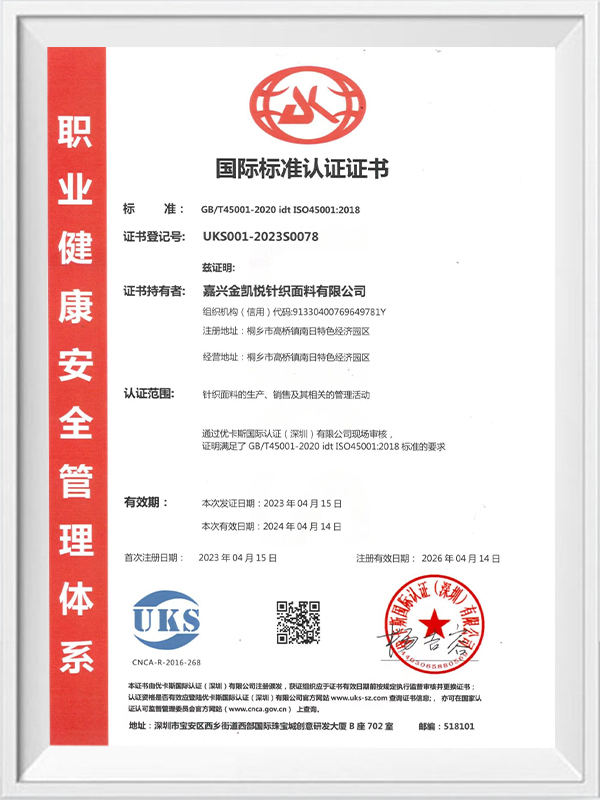

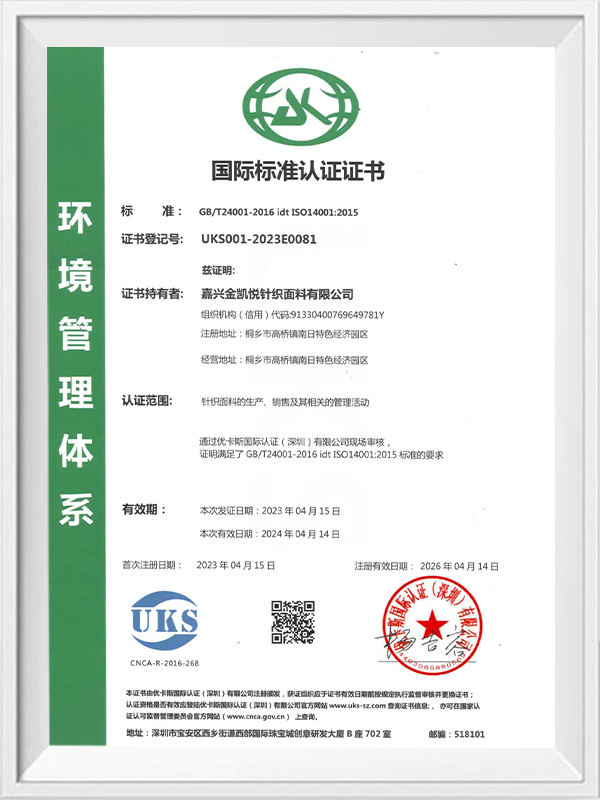

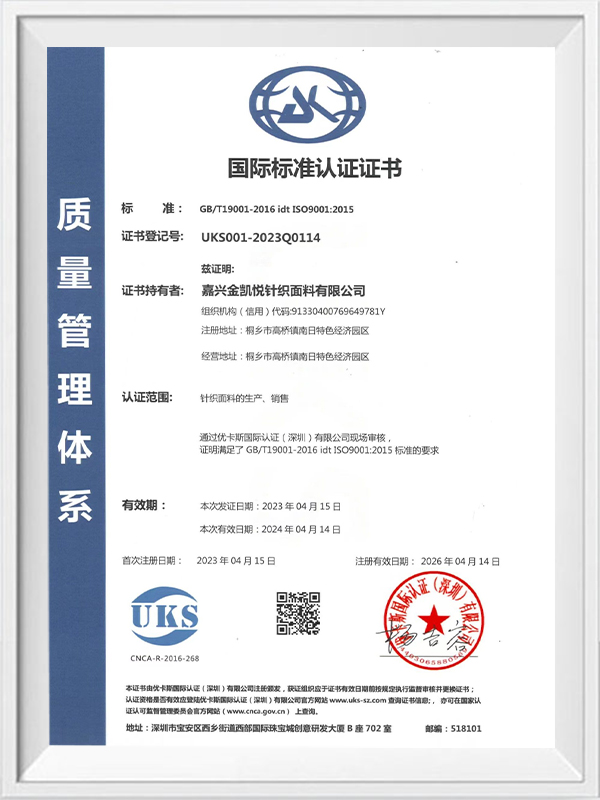

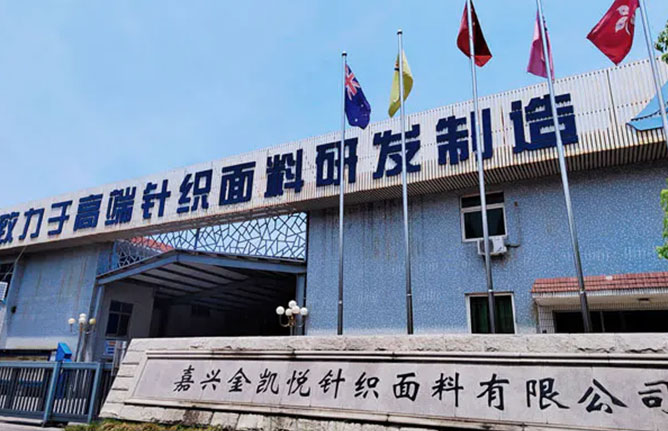

In order to ensure the high quality of pure cotton shirt fabrics, Jiaxing Jinkaiyue Knitted Fabric Co., Ltd. has made a lot of investments in the production process. The company has introduced cutting-edge machines from Italy, Germany, Switzerland, Japan, and Taiwan. These advanced equipment not only improves production efficiency, but also ensures the excellent performance of the fabric in terms of purity, fiber length, and overall quality. By using high-quality raw materials, fine processing technology, strict quality control, and advanced post-treatment technology, the company has successfully produced high-quality pure cotton shirt fabrics and won wide praise and trust from customers.

Ensuring the purity and fiber length of pure cotton shirt fabrics is the key to improving the overall quality of fabrics. High-quality pure cotton shirt fabrics can be produced through the selection of raw materials, fine processing, strict quality control, and the use of advanced spinning, weaving, and post-treatment processes. At the same time, with the help of advanced production equipment and technical support, enterprises can further enhance the competitiveness of their products and meet consumers' pursuit of high-quality life.

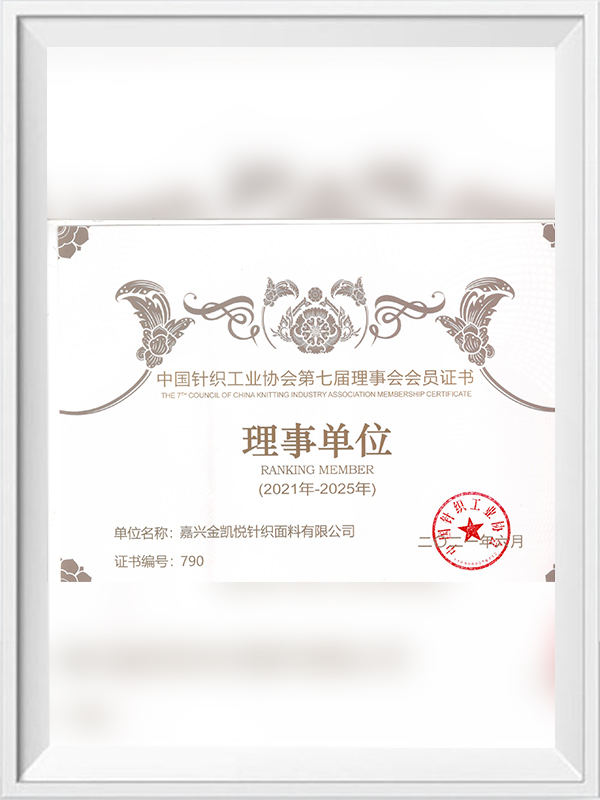

Vores produktionskapaciteter matches af stærke forsknings- og udviklingskapaciteter, hvilket gør os i stand til at levere et stort antal projekter med bedre kvalitet og kortere tidsfrister.

Produktionskapaciteter

Stærke produktionskapaciteter forbedrer din konkurrenceevne

-

For at sikre bedre kvalitet har Jin Hyatt investeret i banebrydende maskiner fra Italien, Tyskland, Schweiz, Japan og Taiwan.

-

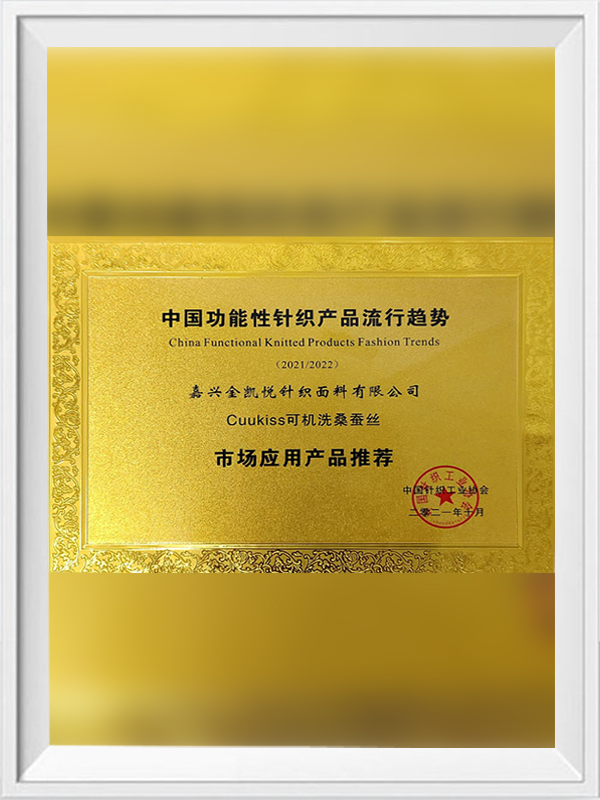

Virksomheden beskæftiger sig primært med en række forskellige materialer, herunder morbærsilke, flydende ammoniakbomuld, uld, kashmir, udendørs sportsstoffer og forskellige fiberblandinger.

-

Virksomheden styrer effektivt opbevaring af råvarer og færdigvarer, integrerer hele produktionsprocessen og forbedrer den samlede effektivitet.

-

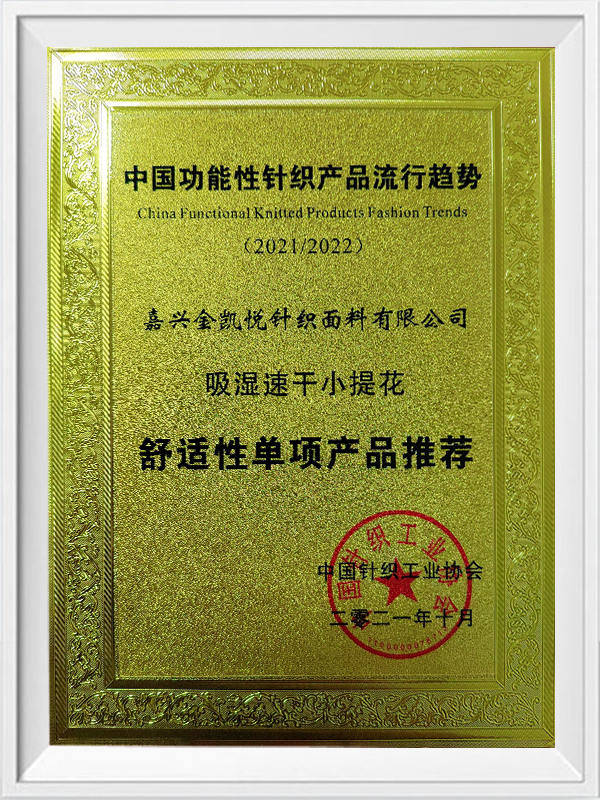

Virksomheden målretter sig mod high-end-markedet med strikkede stoffer af høj kvalitet og bruger 20% af sin arbejdskraft på forskning og udvikling for at forbedre produktets værdi og konkurrenceevne.

中文简体

中文简体